Steel Pipe & Tube Hydrostatic Testers, Steel Pipe & Tube Making Machines, and Metalworking Machinery are integral components of the global steel industry. Whether it is for the construction sector or for industrial applications, steel pipes and tubes are in high demand globally.

The primary use of steel pipes and tubes is for conveying fluids, gases, or solid materials. These pipes have a high resistance to corrosion, making them an ideal choice for heavy-duty applications. Various industries use steel pipes and tubes, including oil and gas, automotive, construction, and manufacturing.

The Steel Pipe Hydrostatic Testing Equipment is used for testing pipes and tubes for their ability to withstand pressure. The hydrostatic pressure testing process ensures that the pipes and tubes are suitable for use in applications that require high-pressure tolerance.

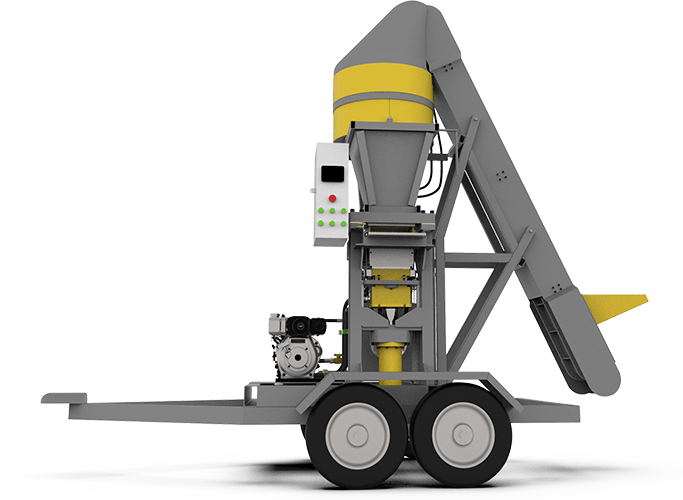

The Metal Pipe Making Machine is used for designing and creating high-quality pipes and tubes in various sizes and shapes. The machine can be used to create square, rectangular, and oval pipes and tubes.

The global steel industry heavily relies on the machinery and tools used in the production process. Steel Pipe & Tube Hydrostatic Testers, Steel Pipe & Tube Making Machines, and Metalworking Machinery are critical components that are essential in the production of steel pipes and tubes.

The production of steel pipes and tubes involves many complex processes, including smelting, casting, forging, rolling, welding, and finishing. Each step requires specialized machinery and equipment to ensure that the pipes and tubes are of the highest quality.

Steel Pipe & Tube Hydrostatic Testers are used to test the pipes and tubes for their pressure tolerance. The hydrostatic pressure testing process involves filling the pipes and tubes with water and increasing the pressure to a level above its working pressure. The pipes and tubes are then checked for any leaks or deformations, ensuring that they have the strength to withstand high-pressure conditions.

Steel Pipe & Tube Making Machines can be used to create pipes and tubes in various shapes and sizes. These machines use specialized processes like hot or cold rolling, welding, and bending to create metal pipes and tubes. Metalworking Machinery is also needed to finish the pipes and tubes, ensuring that they are of the highest quality.

The global steel industry is highly competitive, with manufacturers competing on cost, quality, and delivery time. The use of Steel Pipe & Tube Hydrostatic Testers, Steel Pipe & Tube Making Machines, and Metalworking Machinery is crucial in ensuring that manufacturers produce high-quality steel pipes and tubes that meet the demands of their customers.

The demand for Steel Pipe & Tube Hydrostatic Testers, Steel Pipe & Tube Making Machines, and Metalworking Machinery is on the rise globally. Manufacturers are investing in advanced machinery and equipment, which allows them to produce high-quality pipes and tubes efficiently.

In conclusion, the steel industry relies heavily on Steel Pipe & Tube Hydrostatic Testers, Steel Pipe & Tube Making Machines, and Metalworking Machinery to produce high-quality pipes and tubes efficiently. These machines ensure that products meet the highest standards in terms of strength, resistance, and quality. The demand for these machines is expected to continue to grow as the steel industry expands globally, making them a vital component of the industry's growth.